Construction using LSTK technology (light steel structures)

This is a design, manufacturing and construction technology based on a steel frame using wall and beam profiles for the efficient installation of a load-bearing frame for buildings, which is successfully applied in many countries around the world.

The assembly of the building frame can be carried out at any time of the year due to the absence of wet processes. The panel elements, both wall and ceiling, are delivered to the construction site ready for assembly.

The facade of the building is formed from any material agreed upon with the supervisory services.

The panels are filled with highly effective insulation (based on foam glass, mineral wool or eco-brick), which provides multiple advantages in terms of thermal resistance compared to a wall panel of the same thickness made of traditional materials.

Soundproofing tests have shown high efficiency. This is achieved by combining insulation and air layers.

A vapor barrier and two layers of gypsum board and gypsum fiber are attached to the inside of the frame. These materials are environmentally friendly, easy to transport and install.s

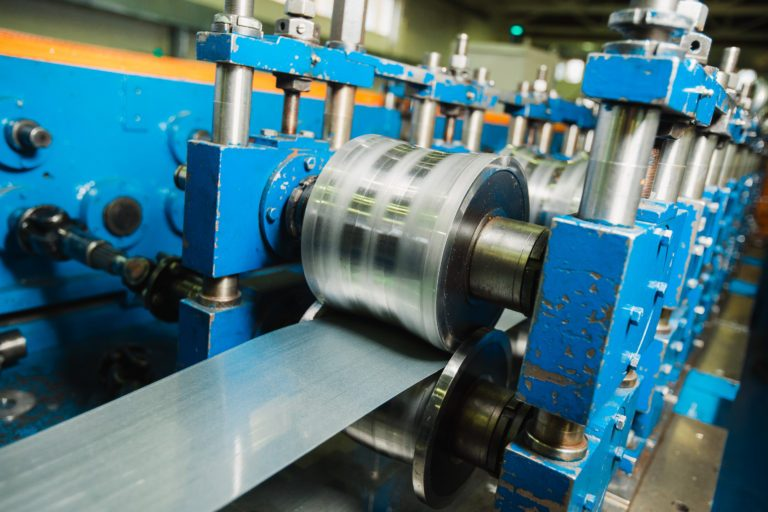

Production technology of LSTC profiles

Computer-aided design and control system equipment allows our factory to quickly create building frames with high accuracy, which reduces the work of installers on the construction site.

The cold steel profiling line is a highly automated complex.

– պրոֆիլի կռում,

– պրոֆիլի հետևի հատվածը կտրելը,

– դակիչ մոնտաժային անցքեր,

– անցքեր անցքեր կոմունալ գծերի համար,

cutting the ends for joining

the parts are not at right angles,

– ծալքավոր մասեր,

– փոսերի դրոշմում մոնտաժային անցքերի համար,

– պրոֆիլի նշումներ:

Not within the range of error

exceeds 1mm/5m. The machine has an automatic calibration system, so all dimensions of the parts are accurate

corresponds to the project. During installation, this gives the necessary advantage in speed and quality, since it is completely

no need

additional work.